ALFA LAVAL HYBRID POWDER MIXER

ALFA LAVAL HYBRID POWDER MIXER M15

Efficient Powder-Liquid Mixing and Pumping Solution

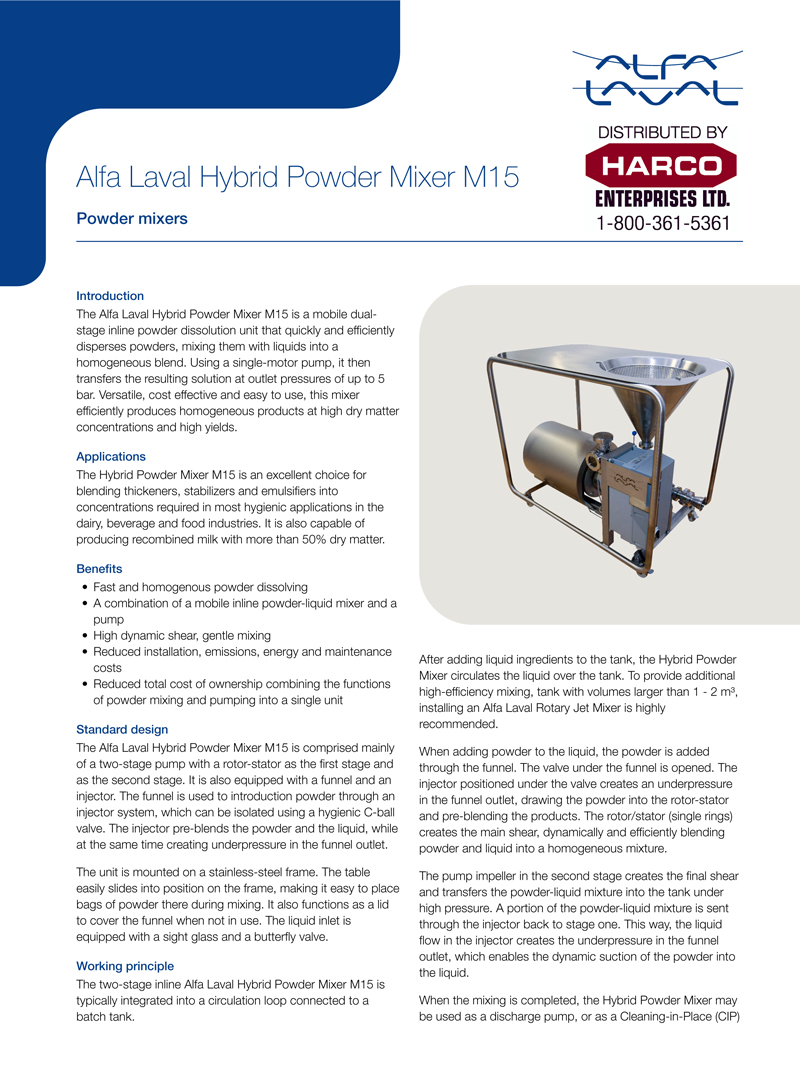

Harco offers the Alfa Laval Hybrid Powder Mixer M15 is a highly efficient, mobile, dual-stage inline powder mixer designed to quickly dissolve powders and seamlessly mix them with liquids into a smooth, homogeneous solution. With its advanced design, this mixer operates using a single motor to pump the resulting mixture at pressures up to 5 bar. Not only does it offer versatility and ease of use, but it also provides a cost-effective mixing solution. Engineered to handle high dry matter concentrations, the M15 Mixer consistently produces uniform blends with high yields, making it ideal for meeting the needs of demanding applications.

Applications

Alfa Laval’s Hybrid Powder Mixer M15 is specifically suited for blending thickeners, stabilizers, and emulsifiers into concentrations required in most hygienic applications in the dairy, beverage, and food industries. Furthermore, its robust performance also makes it ideal for recombining milk with a dry matter concentration of over 50%, supporting hygienic applications that require precise consistency and efficiency.

Benefits

- Fast and homogenous powder dissolving, ensuring optimal product quality

- Dual-function mixer and pump, making it compact and mobile for easy deployment

- High dynamic shear with gentle mixing, which preserves product integrity

- Cost-effective operation with reduced installation, energy, emissions, and maintenance costs

- Reduced total cost of ownership by combining mixing and pumping into a single unit

Standard Design

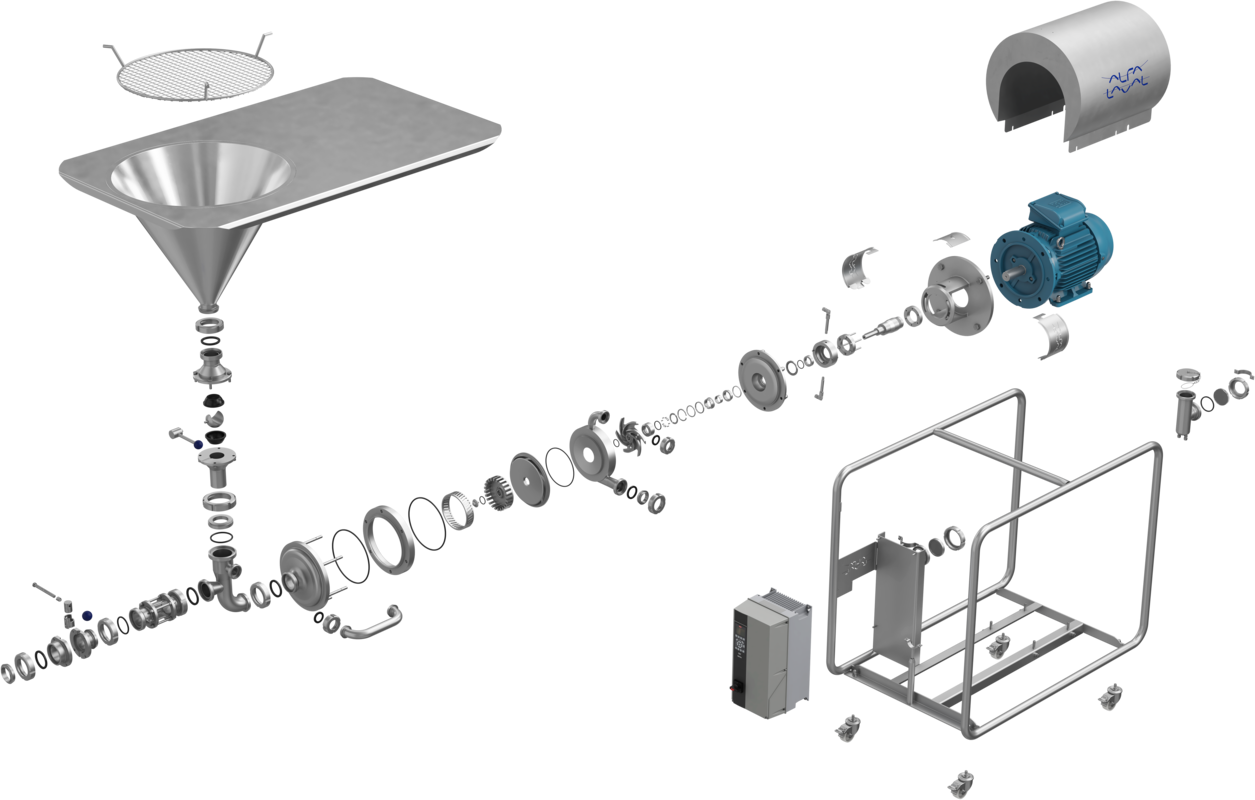

Built with reliability in mind, the Alfa Laval Hybrid Powder Mixer M15 features a two-stage pump setup: the first stage houses a rotor-stator for efficient powder mixing, while the second stage includes an impeller for high-pressure transfer. Additionally, a hygienic C-ball valve isolates the injector system, which pre-blends powder with liquid to create an under pressure in the funnel outlet, thus optimizing powder feeding and dissolution. Mounted on a durable stainless-steel frame, the unit includes a convenient slide-in table that allows for easy placement of powder bags during mixing and doubles as a lid when not in use.

Further design features include a sight glass and butterfly valve on the liquid inlet, ensuring precise flow control during operation.

Working Principle

This two-stage Alfa Laval Hybrid Powder Mixer M15 is typically integrated seamlessly into a batch tank circulation loop. First, the liquid circulates through the mixer, drawing powder through the funnel and injector. This process creates an under pressure that pulls powder into the rotor-stator, blending it dynamically with the liquid. Then, the pump’s impeller applies final shear, delivering a homogenous mix under high pressure back to the tank.

For larger tanks (over 1-2 m³), installing an Alfa Laval Rotary Jet Mixer is highly recommended, as it enhances overall mixing efficiency. Once mixing is complete, the Hybrid Powder Mixer M15 can function as a discharge pump or as a Cleaning-in-Place (CIP) recirculation pump, which simplifies cleaning and maintenance when used alongside Alfa Laval rotary jet mixing systems.

In conclusion, the Alfa Laval Hybrid Powder Mixer M15 is your ultimate solution for streamlined, efficient powder-liquid mixing. By setting a high standard in reliability and performance, it addresses the unique requirements of the food, beverage, and dairy industries.

For more information contact us at 1-800-361-5361 or 705-743-5361, or [email protected]