ALFA LAVAL HYBRID POWDER MIXER

ALFA LAVAL HYBRID POWDER MIXER S15

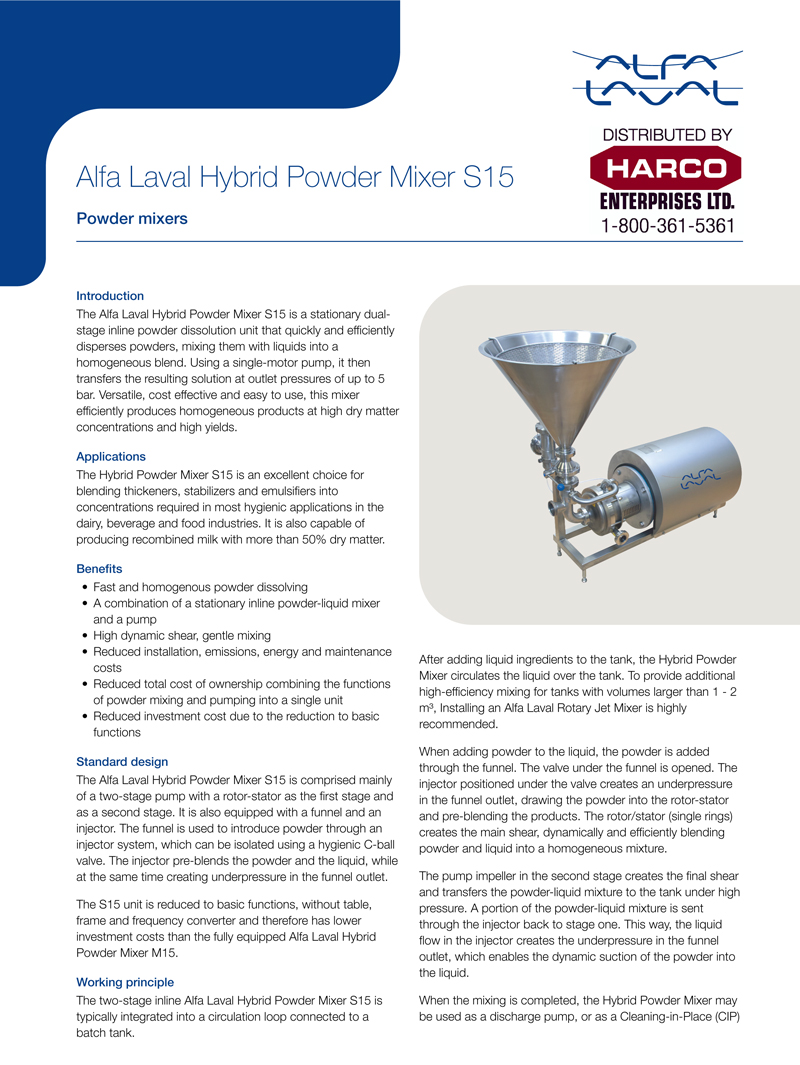

Harco offers the Alfa Laval Hybrid Powder Mixer S15, a stationary, dual-stage inline powder dissolution unit expertly designed to rapidly and efficiently mix powders with liquids, resulting in a uniform blend. Operating with a single-motor pump, it then transfers the resulting mixture at outlet pressures up to 5 bar, ensuring high-quality mixing for a variety of applications. With its cost-effective, versatile, and easy-to-use design, this mixer S15 efficiently produces homogeneous products at high dry matter concentrations and high yields, making it ideal for hygienic industries.

Applications

Alfa Laval’s Hybrid Powder Mixer S15 is an excellent choice for blending of thickeners, stabilizers, and emulsifiers into concentrations required in most hygienic applications in the dairy, beverage and food industries. Additionally, it is also capable of producing recombined milk with more than 50% dry matter, showcasing its capability in applications that demand precision and efficiency.

Benefits

- Fast and homogenous powder dissolving

- A combination of a stationary inline powder-liquid mixer and a pump

- Delivers high dynamic shear with gentle mixing

- Minimizes installation, emissions, energy, and maintenance costs

- Lowers total cost of ownership by combing mixing and pumping into a single unit

- Reduced investment cost due to the reduction to basic functions

Standard Design

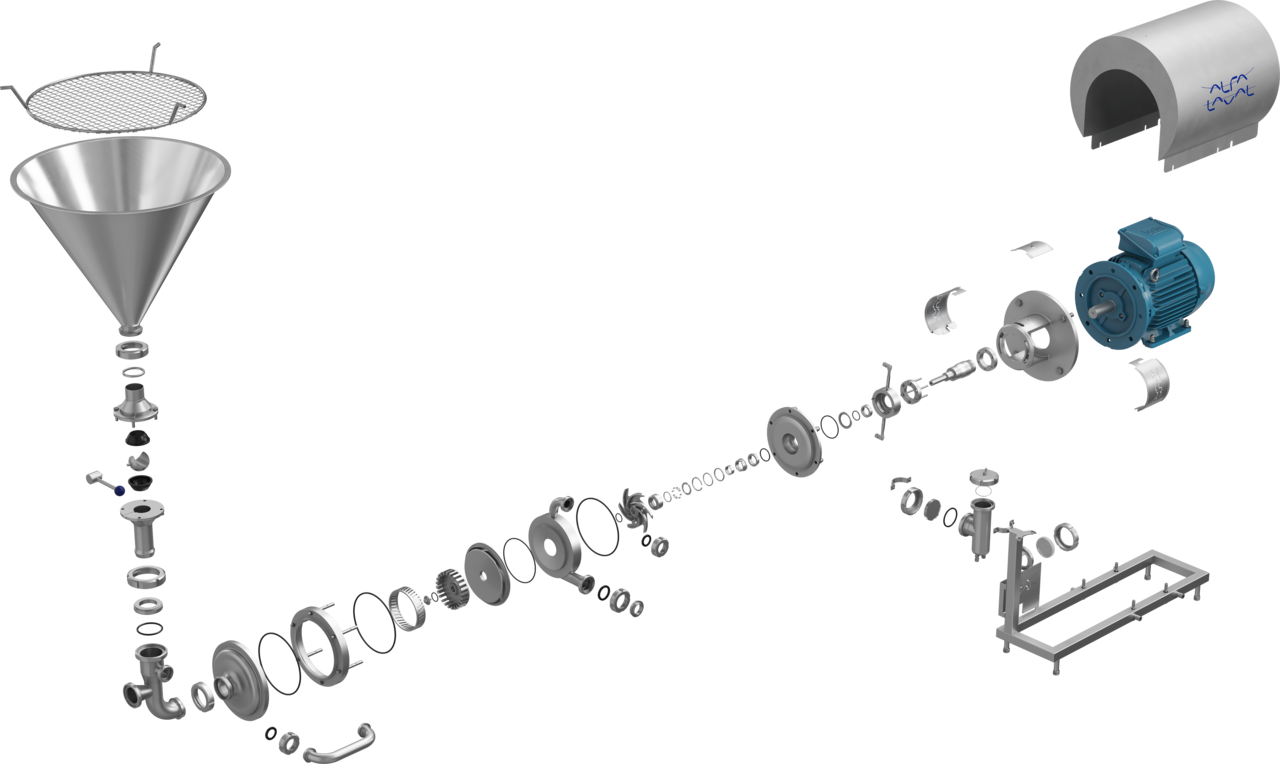

The Alfa Laval Hybrid Powder Mixer S15 mixer features a two-stage pump with an initial rotor-stator for high shear mixing, complemented by a second-stage pump for efficient transfer. It includes a funnel and injector for powder introduction, where the injector system isolates the funnel via a hygienic C-ball valve. This setup facilitates an efficient pre-blend of powder and liquid through under-pressure creation, preparing it for further blending in the main rotor-stator.

As a streamlined model, the S15 reduces investment costs by focusing on core functionalities and omitting additional components like a frame, table, and frequency converter.

Working Principle

In a typical setup, the Hybrid Powder Mixer S15 from Alfa Laval integrates seamlessly within a circulation loop connected to a batch tank. Liquid ingredients are first added to the tank, and the mixer circulates them to achieve a uniform blend. For larger tank volumes (above 1–2 m³), an Alfa Laval Rotary Jet Mixer is recommended to enhance mixing efficiency.

When adding powder, the Alfa Laval Hybrid Powder Mixer S15 draws powder through the funnel into the rotor-stator, creating an effective pre-blend under pressure. Then the two-stage inline pump delivers the final mixture to the tank, where part of it cycles back to generate continuous suction. Therefore, this dynamic flow ensures efficient powder incorporation and results in a smooth, homogeneous mixture.

The Alfa Laval Hybrid Powder Mixer S15 also doubles as a discharge pump or a CIP recirculation pump when paired with an Alfa Laval Rotary Jet Mixer, providing a complete solution for mixing and cleaning in hygienic applications.

For more information contact us at 1-800-361-5361 or 705-743-5361, or [email protected]