Unique Mixproof Valves

ALFA LAVAL UNIQUE MIXPROOF PROCESS VALVES

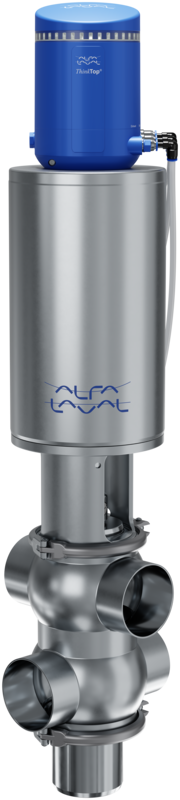

Protect your process fluids and ensure operational integrity at valve matrices and pipelines with the Alfa Laval Unique Mixproof Process Valves. These cost-effective, versatile, double block-and-bleed valves are an economical version of our premium double seat Mixproof valves with seat-lift, designed to eliminate the risk of cross-contamination. It allows for the simultaneous flow of two products or fluids through the same valve without compromising safety.

Featuring high cleanability, the ability to withstand pressure peaks, and fit-for-purpose components, these Alfa Laval Unique Mixproof Process Valves are an excellent addition to dairy, food, and beverage applications. Available in various sizes, it meets your fundamental hygienic processing requirements, ensuring your operations run smoothly and safely.

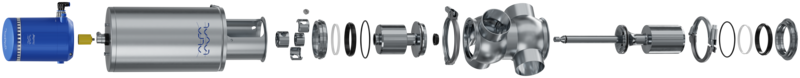

Alfa Laval’s Unique Mixproof Process Valves are a fit-for-purpose double seat valve with a seat-lift function. Based on the proven Alfa Laval Unique Mixproof Valves and Alfa Laval Unique Single Seat Valves, it holds certifications from FDA, 3A, and other recognized standards, ensuring uncompromised quality.

Experience unparalleled product protection, even under high pressures, with the Alfa Laval Unique Mixproof Process Valves. Its modular design makes it easy to adapt to various applications, capacity requirements, and evolving needs, ensuring versatility and efficiency.

Simplified Maintenance and Cost Efficiency

Service is made effortless with a maintenance-free actuator and proven seal technology with defined compression that prolongs the time between maintenance intervals. Elevate your sustainability efforts by pairing these valves with an Alfa Laval ThinkTop valve control unit, unlocking up to 90% savings in water, cleaning media, and wastewater costs.

Applications for the Alfa Laval Unique Mixproof Process Valve

The Alfa Laval Unique Mixproof Process Valves are meticulously engineered to ensure uninterrupted flow control and uphold stringent safety standards in hygienic processes. With a primary focus on product safety, they serve as a cornerstone solution across various industries including dairy, food, beverage, and more.

Benefits

- Get the product safety you need by eliminating the risk of cross-contamination and product loss while ensuring efficient cleaning

- Enhance the reliability and flexibility of your process setup with proven valve technology tailored to your specific production needs, minimize the risk of unplanned downtime while spending as little time and resources as possible on routine maintenance

- Limit your environmental impact with significantly reduced water and CIP media consumption, no spillage and eliminated product loss

- Predefined and available in various sizes to meet your fundamental hygienic processing requirements